We are delighted to welcome you back as Innov8 Hub officially resumes operations for the new year. A new year brings renewed energy, fresh opportunities, and a chance to build on the progress we have made together. As we reflect on the past year, we are proud of the milestones achieved, the ideas nurtured, and the impact created through collaboration,

Author: Super Admin

Celebrating Innovation at Innov8 Hub: SGCI Demo Day Showcases Indigenous Tech Solutions

The Science Granting Councils Initiative (SGCI) is a one-year, intensive capacity-building and product development journey designed specifically for academics, researchers, and innovators, particularly those alumni from the Research for Impact (R4I) program. The SGCI initiative plays a key role in strengthening national research and innovation ecosystem by implementing competitive funding schemes that stimulate high-impact research and innovation in tertiary institutions.

Transformative Innovation Workshop (TIW) Closing Event at Innov8 Hub

The Transformative Innovation Workshop (TIW) is a hybrid program designed to drive community- and institution-focused research and innovation. TIW empowers participants to identify real challenges within institutions and their surrounding communities, and to co-create practical solutions that address them. The program bridges the gap between academic or institutional insight and real-world application, through a deeply experiential learning model. The program

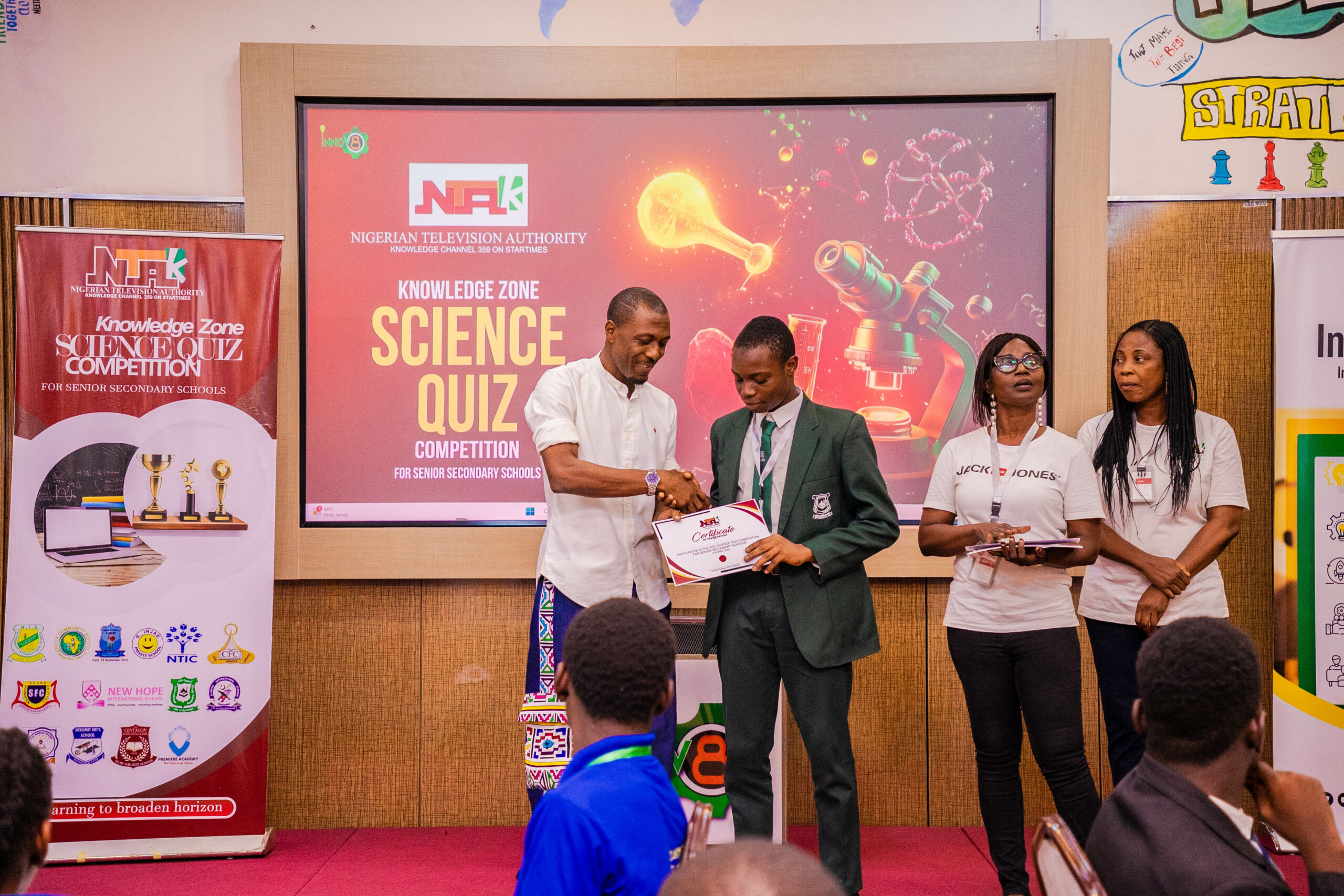

NTA Knowledge Science Quiz Competition —Inspiring the Next Generation

The NTA Knowledge Science Quiz Competition is a dynamic, science-driven contest aimed at igniting curiosity and deepening scientific awareness among secondary school students. This engaging platform offers young learners the opportunity to showcase their intellect, sharpen their critical thinking skills, and gain exposure to real-world scientific concepts. This edition brought together 11 schools from Abuja and its environs, each represented

IP Salaye—Empowering Corps Members Through Intellectual Property Awareness

IP Salaye is a transformative initiative designed to empower Nigerian corps members by equipping them with vital knowledge about Intellectual Property (IP) and the importance of safeguarding their innovations. This initiative, driven in collaboration with the World Intellectual Property Organization (WIPO) and Innov8Hub, recognizes the immense potential within Nigeria’s youth, especially those serving through the National Youth Service Corps (NYSC).

Partnerships & Collaboration: Acting US Ambassador to Nigeria Visits Innov8 Hub

As part of the mandate of establishing an ecosystem of innovation, start-up incubation and venture creation through partnerships & collaboration, Innov8 Hub extended a cordial welcome to David Greene, the Acting Ambassador of the United States of America in Nigeria, and his team, as they paid a courtesy visit.

My TETFAIR Journey: ENGR. EZEEMO U. JOSIAH

The idea that brought me to TETFAIR can be traced back to my studio, just before my appointment as a lecturer at Nnamdi Azikiwe University. In Nigeria’s textile industry, small and medium-sized textile cottage enterprises are plagued by the

absence of fast-paced and effective drying and curing methods, leading to inefficient production, inconsistent quality, and inflated cost.

My TETFAIR Journey: PROF. AYOTUNDE OLUTUMININU ADEBAMBO

Federal University of Agriculture, Abeokuta My TETFAIR journey began out of necessity. The strain placed on animals, farmers and researchers during the routine measurement of the morphometric characteristics of poultry birds is intolerable. These measurements are crucial for making informed decisions on the growth, development, and health status of birds and the poultry business by extension. The archaic method of

My TETFAIR Journey: PETER GAI

My TETFAIR journey commenced when a team of researchers from Abubakar Tafawa Balewa University, Bauchi, conceived the idea of utilising basalt-based composite material for the production of vehicle brake pads. In the operation of vehicles, few components carry as much significance and importance as the brake pad.

My TETFAIR Journey: ABUBAKAR SHINKAFI (PhD)

Reflecting on my TETFAIR experience, I have undergone a significant shift in mindset—from a primarily research-based approach to one that leans more towards innovation and enterprise. TETFAIR acted as a catalyst for translating my academic ideas into a real-world business context.